Industrial Tank Cleaning

Tank Cleaning Services

Adler Companies is your single source for industrial tank cleaning, with over 40 years of experience. Our experienced team and cutting-edge equipment can clean almost any storage tank, regardless of its size and substance. Schedule ahead for a regular cleaning or call us 24/7 for emergency response. Our fleet of 22 industrial state-of-the-art high-powered vacuum trucks and properly trained technicians are qualified to clean tanks containing both hazardous and non-hazardous materials including:- Oil Tank Cleaning

- Fuel Tank Cleaning

- Storage Tank Cleaning

- Underground Storage Tank Cleaning/ Removal

- Silo Cleaning

- Frac Tank Cleaning and More

Benefits of Adler Tank Cleaning

- Fully Insured

- 40+ Years of Experience

- State-Of-The-Art Vacuum Trucks

- 24/7 Emergency Response

- Cost Effective

- 21 Yard Debris Box (Industry Standard of 15 yards)

- Safety Certified

- Reduced Liability

Why Choose Adler Tank Cleaning

SAFETY, PRODUCTIVITY, DEPENDABILITY

We have been family-owned and operated for the past 40 years and are still going strong. We were the main vac truck contractor in 2001 doing the clean-up of the World Trade Center disaster, Hurricane Sandy, and BP Oil spill in the Gulf. We’ve worked over the years for literally 1000’s of general contractors, building owners, municipalities and manufacturers. Many of our employees have been with us over 20 years which is the real benefit in dealing with our company. Knowledge and expertise yields efficiency and safety which together will save you time and money in the long run.VERSATILITY + SUPERIOR SERVICE GUARANTEED

With Adler, you will find a positive solutions oriented attitude. Our team is always accessible and eager to respond to your needs. At every level of our organization, you will see a commitment to consistently high customer satisfaction. We are driven to be your single source for all of your industrial tank cleaning needs.

The Best Trucks in The Industry

Explore Our Hydrovac Truck Specs:- Height: 13′

- Length: 39′

- Water Tank: 1200 Gallons

- Water System: 10 GPM at 2500 RPM

- PD Vacuum: 5250 CFM at 2000 RPM

- Boom: 7′ with 320 Degrees Rotation

- Heavy Duty, Self-Grounding Rubber Hose: 22” From Centerline Of Truck

- 21 Yard Debris Box (Industry Standard Of 15 Yards)

Serving the industry for over 40 years, we clean almost any vessel containing any substance.

Industries Served By Adler Tank Cleaning

Adler offers a wide range of industrial tank cleaning services. Being the industry leader for over four decades, our expert team will assess your project and plan out the most cost-effective solution to complete your project with minimal downtime. It is critical to keep your process vessels and tanks clean for them to operate efficiently and at maximum capacity. Listed below are just a few of the industries which we serve:

Oil Tank Farms

Petroleum Refineries

Chemical Plants

Manufacturing Facilities

Power Generating Facilities

Transportation Companies

Food Storage Facilities

24 hour turnaround time

Get A QuoteApplications for Tank Cleaning

We alter our cleaning process keeping your needs and goals in mind working closely with the project coordinator to exceed your expectations. Serving the industry for over 40 years, we clean almost any vessel containing any substance. Some of the tank cleaning applications we specialize in include:

Oil/Fuel Tank Cleaning

Prolong the durability of your oil/fuel tank with Adler’s tank cleaning services. Our professional team can clean, dismantle, remove the tanks and connected piping. Adler can provide site remediation services after oil/fuel storage tank removal to keep your working facility clean and safe.Storage Tank Cleaning

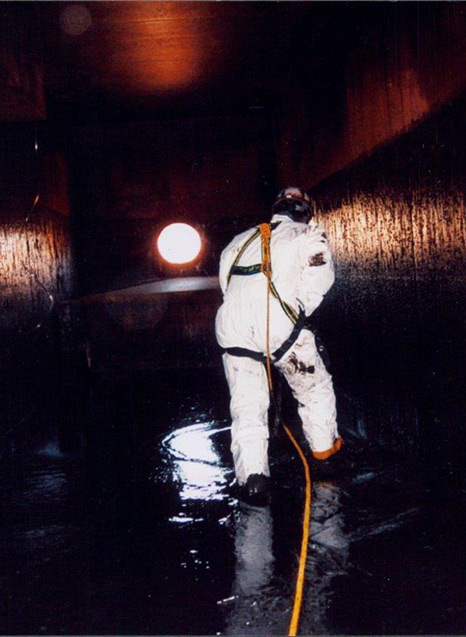

Adler industrial tank cleaning services are suitable for a variety of aboveground storage tank sizes and configurations. We specialize in chemical and petrochemical waste tank cleaning and decommissioning. Adler’s expert crew is OSHA certified to work in confined spaces, and can provide a clean gas-free tank safely and in a timely manner.

Underground Storage Tank Cleaning/Removal

Adler specializes in removal of any residual materials from underground tanks. If your project also requires underground tank storage removal. Then after cleaning is completed. Adler will properly dispose of the waste obtained from inside the tank. This strategic process is aligned with environmental safety. The next step is to inert the tank, as a means of eliminating the risk for explosivity. Finally the ground around the tank is removed and the excavation begins. Adler is then able to dispose of the tank.

Silo Cleaning

Silo cleaning maximizes the efficiency of storage silos that hold bulk powders or granules. Such as pet food, grains, industrial powders, cement, pharmaceuticals etc. Because the stored materials tend to cluster. Clogged silos or bins are very common. Manual cleaning is highly dangerous in this case because of the possible gas poisoning or falling materials that can severely injury workers. Adler’s silo cleaning technique is the safest because human entry is not required.

Frac Tank Cleaning

Frac tanks commonly store liquids or solids like petroleum, chemicals, mud or manure, and are used across many industries. In order for frac tanks to be reused or returned to the rental company they need to be cleaned. Adler’s hydrovac or industrial vacuum truck can perform the job safely and in a timely manner. With Adler your project will be complete with quality control measures guaranteeing you no risk of contaminants left in the tanks.Click to Explore Our Other Services

Tank Cleaning Services for the Entire Eastern Seaboard

We provide tank cleaning services for the following areas:

- Maine

- New Hampshire

- Vermont

- Massachusetts

- Rhode Island

- Connecticut

- New York

- New Jersey

- Pennsylvania

- Delaware

- Ohio

- Michigan

- Wisconsin

- Illinois

- Indiana

- Washington DC

- West Virginia

- Virginia

- Kentucky

- North Carolina

- South Carolina

- Georgia

- Tennessee

- Mississippi

- Alabama

- Florida

Safety Is Our Priority

- Compliance with Adler’s health and safety policy

- Compliance with all government, client-specific, or site-specific requirements

- 40 hour hazmat training

- Confined space training

- Full medical cards on drivers

- Physicals and fit tests on employees

- Random drug tests

- Site specific training on all jobs- Tail Gate Safety Meetings

- Appropriate clothing and protective equipment

- Immediate identification and report of safety hazards or unsafe work conditions